The Custom Fabrication Process

Once your scoliosis team of experts have taken all your patient information, measurements and prescribed the orthosis design customized to meet your requirements, they send us any photos, scans and shape profile with the order.

General Information Received

- Specified patient information, including age, height, weight, and diagnosis are received.

- Prescribed orthosis design, customized to meet the requirements for that individual patient

- Detailed anatomical patient measurements, and shape definition profile information

- Any additional supporting materials, such as photos or scans, supporting the design and accuracy of the orthosis.

When Spinal Technology receives the order, every detail and specification is reviewed by our senior fabrication specialists and a custom mold is fabricated to match your exact anatomical measurements.

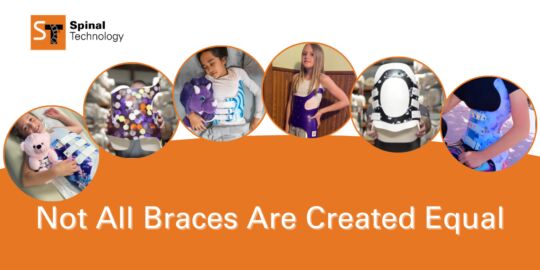

If you choose a colorful transfer pattern or any decals, those get heated in the oven then they are formed and cured around the brace mold. The mold then is hand cut to the shape of your prescribed brace, the edges are buffed for comfort and all the necessary hardware, such as straps and buckles are added.

Our quality team inspects each brace one by one to ensure all design parameters have been met. Then we ship the finished product to your clinician who will fit and make any adjustments needed for maximum comfort.